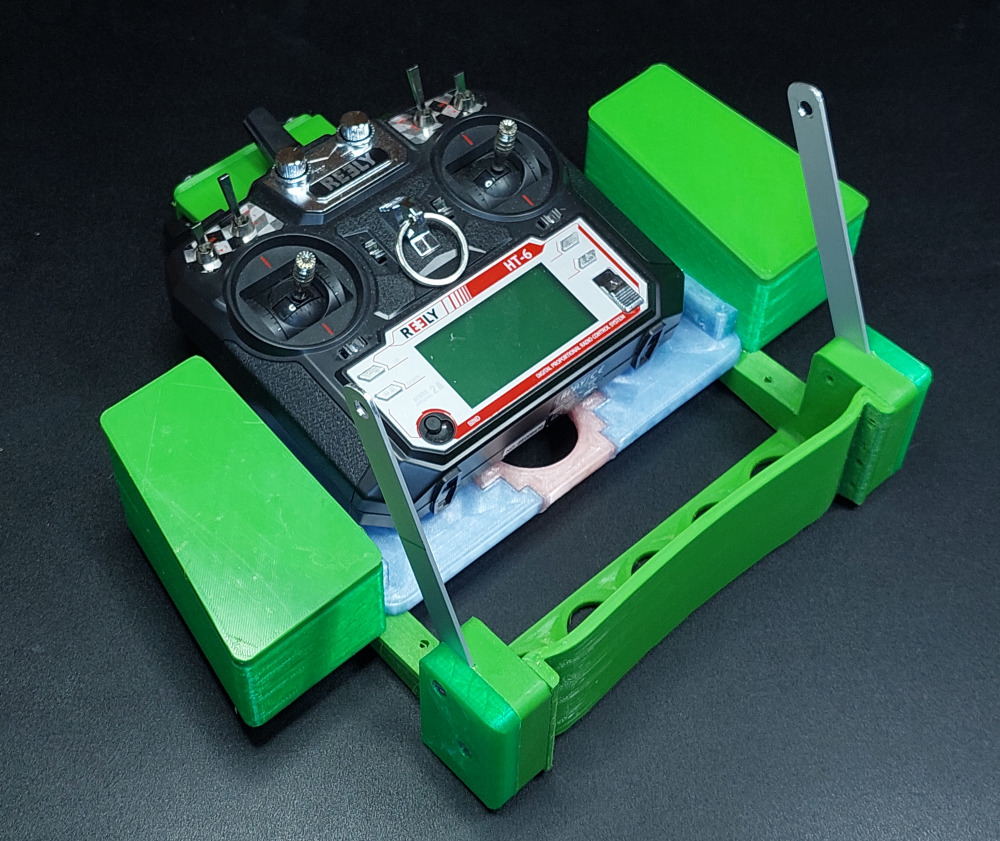

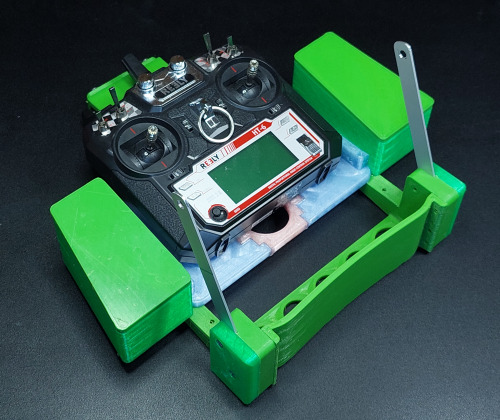

Transmitter console

The transmitter console consists of

several 3D printed parts that are glued

together with epoxy resin.

It is made to be used with a

variety of handheld transmitters. With an

optional extension, the console can be adapted to different

transmitter shapes and sizes.

n

addition to the 3D printed parts, you also need two aluminum

rods, round magnets and some screws.

The individual parts should be printed from PETG, which has

significantly higher thermal stability than

PLA.

When designing and printing the parts for my RC flight models, I

use PrusaSlicer, which can be

downloaded from https://www.prusa3d.de/prusaslicer/,

to realize special desired properties

for 3D printed parts. These properties (e.g. adhesive surfaces

or internal support structures) cannot be

achieved at all or only with great difficulty using a CAD

program alone.

I use modifiers in

Prusaslicer, which are essential for building this glider. For

this reason I do not provide stl-files,

but 3mf-files for download. If you still need stl files,

here (Video: Extract

stl-files out of 3mf-files) you will find a link on how

stl files can be exported in

PrusaSlicer.

The print files can be downloaded on Printables.com:

https://www.printables.com/de/model/286916-little-acro

On YouTube I have published a step-by-step build video of the transmitter console:

Materials needed

- Filament: PETG ca. 450 Gramm

- Aluminium rods: 160 mm x 15 mm x 2 mm (lxwxt): 2 pieces

- Screws M4: Length 16 mm: 16 pieces

- Magnets: Diameter 6 mm, height: 2 mm: 8 pieces

Preparations for assembly

After printing the individual parts, they must be deburred.

All adhesive surfaces must be roughened

with 80 or 120 grit sandpaper. This is important for parts made

of PETG, otherwise the glue joints will

not be stable!

The parts must be glued with 5-minute epoxy resin. Superglue is too brittle for this application!

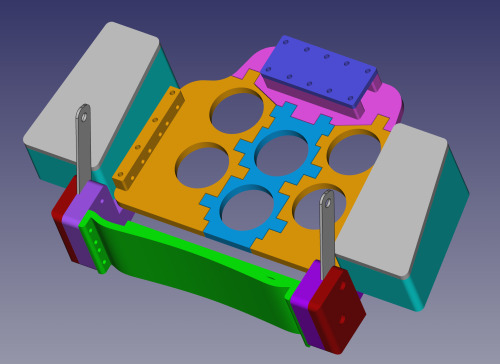

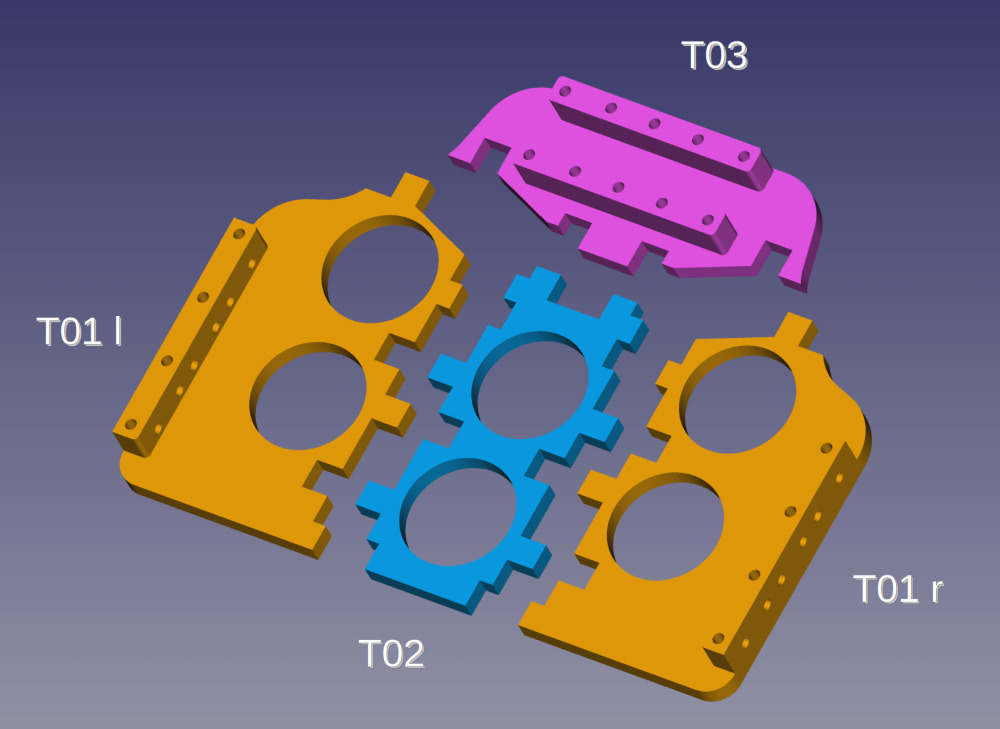

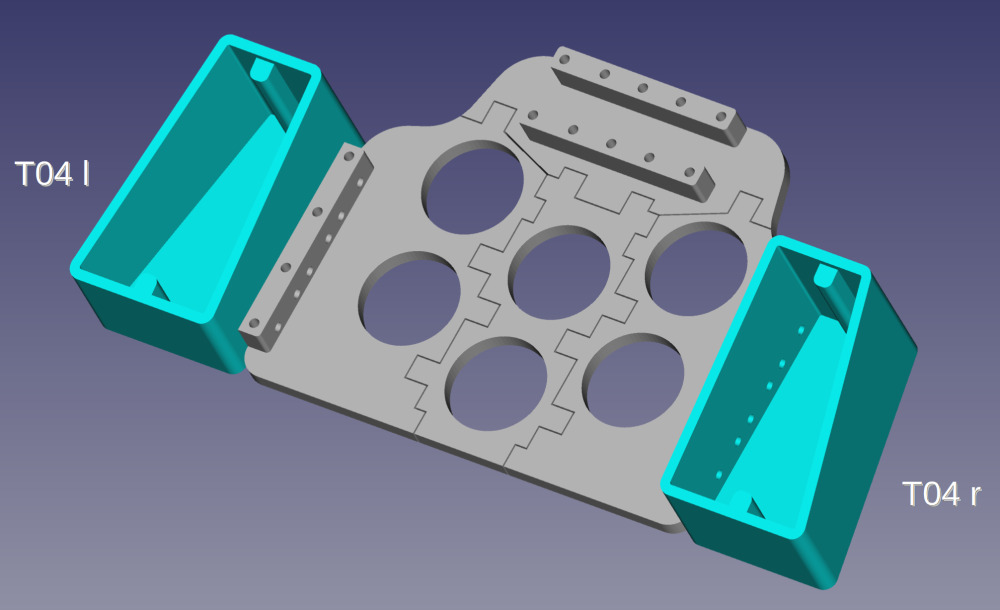

Step 1: Building the base plate

The base plate is made of four parts that are glued with epoxy resin.

Allow the glue joints of the pieces to cure on a flat

surface.

A surface (e.g. laminating film) to

which the epoxy resin does not stick is helpful.

Step 2: Side parts

The two side parts are glued on with epoxy resin.

Align the pieces on a flat surface. The holes act as a guide.

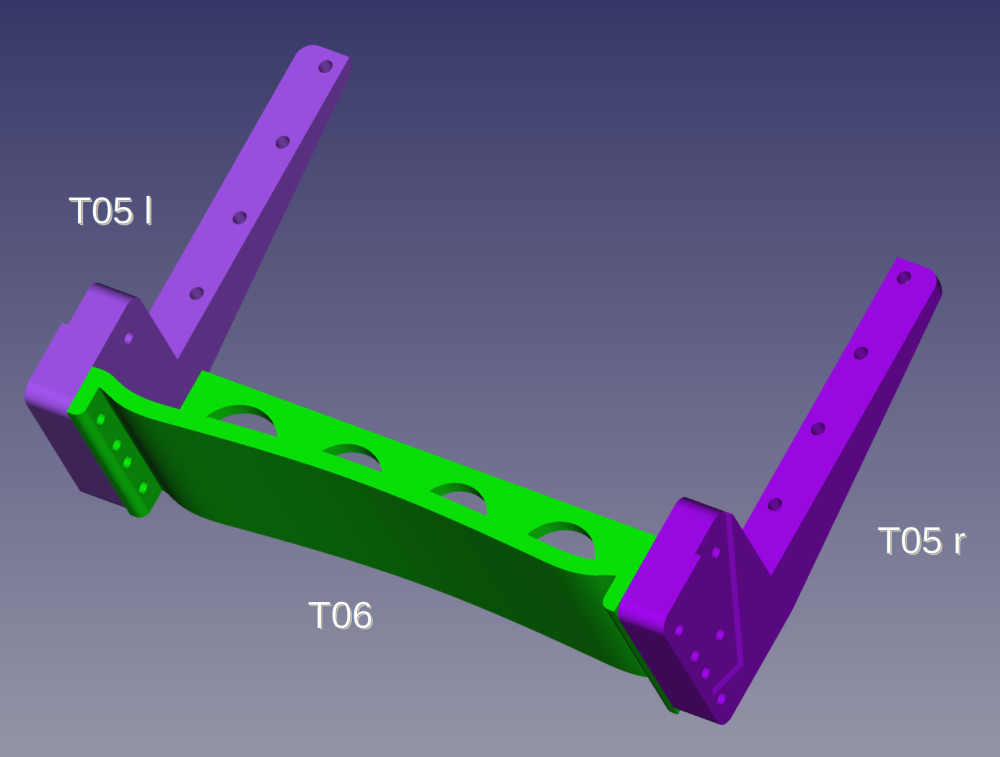

Step 3: Bracket

The bracket is made of three parts that are glued together with epoxy resin.

Use a sufficient amount of epoxy resin for the adhesive

surfaces, as the parts are essential for the

stability of the transmitter console.

Align the pieces on a

flat surface. Use clamps to hold the

parts in place while the resin is curing.

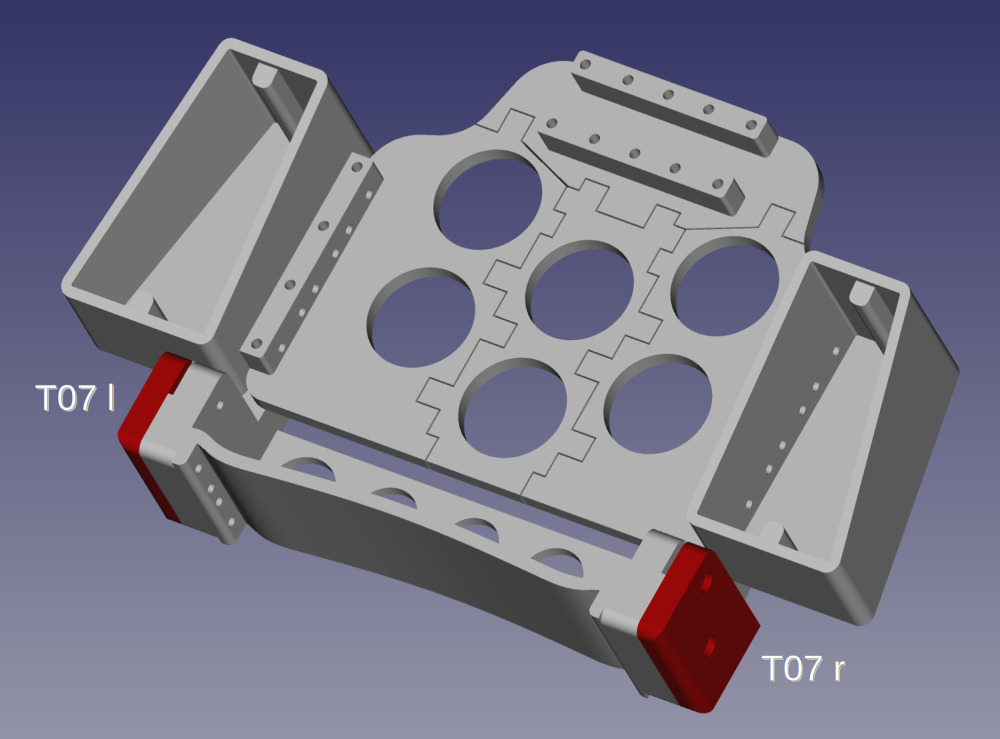

Step 4: Connecting the base plate to the bracket

The bracket and the base plate are glued with sufficient epoxy

resin.

Make sure to align the base

plate to match the size of your transmitter.

Before gluing,

take measurements with your transmitter.

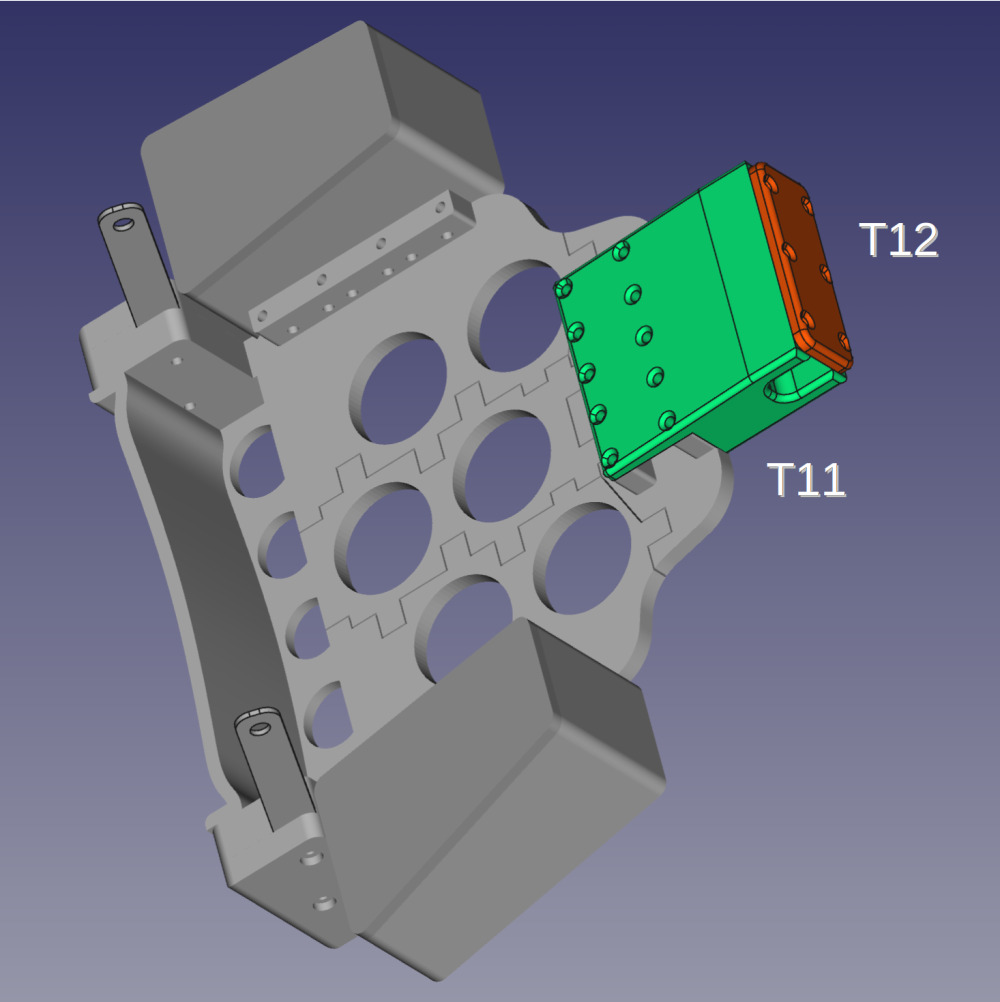

If necessary, use the optional extension (parts T11 and

T12).

You must be able to

operate the transmitter sticks and switches well and

comfortably. The aluminum rods that run angled to

the front must not be in the way.

Once the adhesive point has hardened, glue the side parts T07 to the side of the bracket. You can use superglue for this, as the bracket and aluminum rods will be connected with screws.

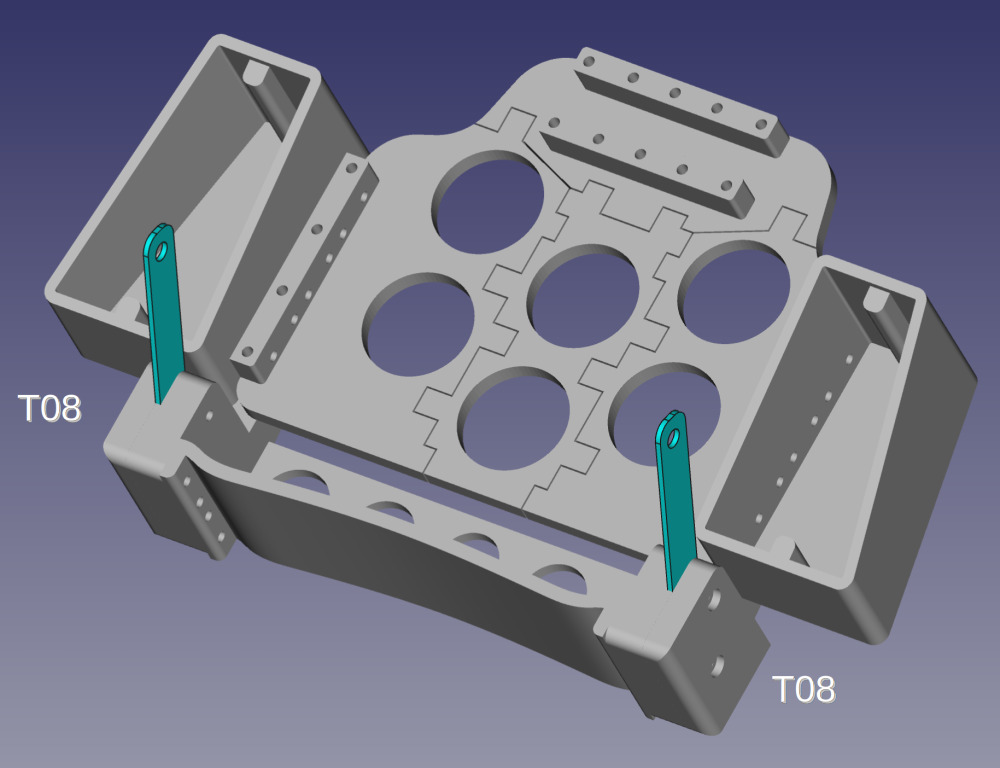

Step 5: Aluminum support rods

The aluminium support rods are made from a

15 x⊟2 mm aluminium bar.

The length of

the rods can be adjusted to your own preferences. It is between

130 and 200 mm.

The aluminium

rods are rounded at one end. A hole for the neck strap (6 bis

8 mm diameter) is drilled at the

rounded edge.

Slide the rods into the sides of the bracket so you can

pre-drill the holes for the mounting screws with

a 3,5 mm drill bit. However, do not drill completely

through the aluminum rods.

Remove the

aluminum rods and drill the holes at the marked locations to

5 mm diameter.

Put the finished drilled rods back into the sides of the

bracket

Do not glue the rods in place!

The rods are

screwed to the bracket wirht

M4 x 16 mm screws.

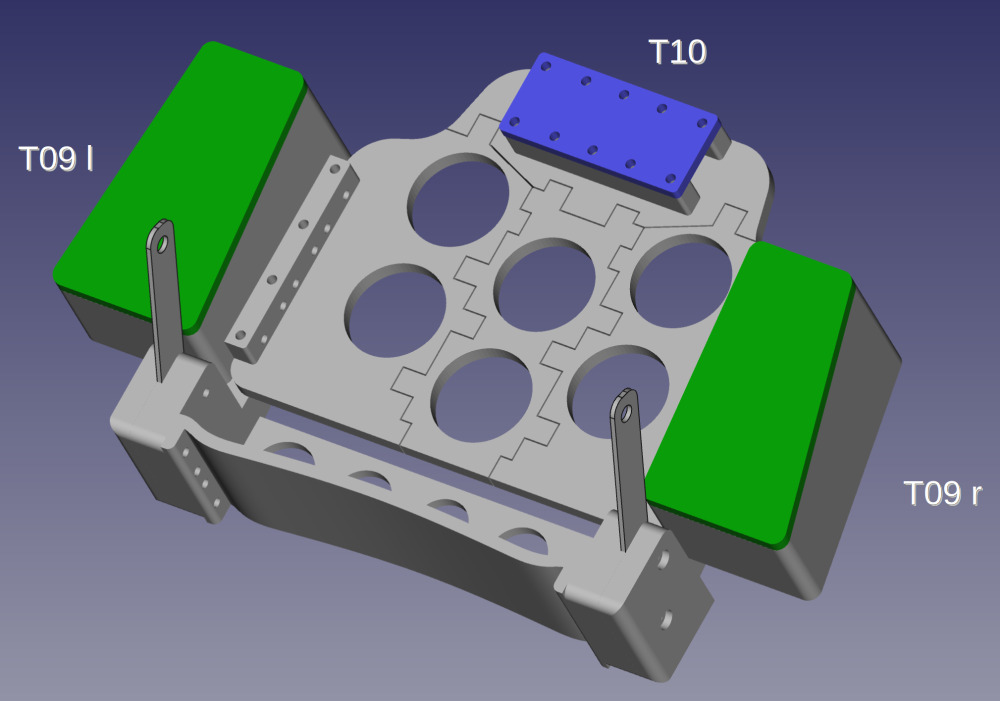

Step 6: Attach the transmitter and side covers

Now attach the transmitter on the base plate. Secure the holding bracket of the transmitter with the holding plate T10. The holding plate is screwed tight with M4 x 16 mm screws.

The lids T09 for the side panels are fixed with magnets. The magnets are glued with superglue to the lid and the inside of the side panels.

Optional: Extension of the base plate

If the base plate is too short for the transmitter, you can use the base plate extension (parts T11 and T12).

Pictures